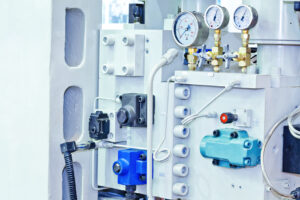

Pressure gauge glass, also known as the gauge window, is a crucial component that protects the dial and internal mechanism of the pressure gauge. It ensures clear visibility of the readings while providing durability and resistance to environmental conditions.

Importance of Pressure Gauge Glass

The glass covering the pressure gauge dial serves several essential functions:

- Protection – Shields the gauge’s internal components from dust, moisture, and external impacts.

- Clarity – Ensures easy readability of the pressure values.

- Durability – Resists high temperatures, pressure fluctuations, and corrosive substances.

Types of Pressure Gauge Glass

There are several types of glass used for pressure gauges, each offering distinct advantages:

- Tempered Glass – Heat-treated for enhanced strength and safety; resists shattering under high pressure.

- Laminated Glass – Composed of multiple layers with an interlayer for added protection; prevents shattering.

- Borosilicate Glass – High-temperature and chemical-resistant, ideal for harsh industrial environments.

- Acrylic or Polycarbonate Lens – Lightweight and impact-resistant, commonly used for gauges in less extreme conditions.

Selecting the Right Pressure Gauge Glass

Choosing the appropriate gauge glass depends on the working environment and application. Factors to consider include:

- Operating Pressure and Temperature – Higher pressures and temperatures require more robust materials like borosilicate or tempered glass.

- Exposure to Chemicals – Corrosive environments demand chemically resistant materials.

- Impact Resistance Needs – In areas prone to mechanical shocks, laminated or polycarbonate lenses may be preferable.

Pressure gauge glass plays a vital role in ensuring the accuracy, longevity, and reliability of pressure gauges. Selecting the right type based on operational conditions enhances gauge performance and safety. As industrial demands evolve, advanced materials continue to improve gauge durability and efficiency.