Pressure gauges are critical components in the oil and gas industry, where they play a vital role in ensuring the safety, efficiency, and reliability of operations. In this sector, pressure gauges are used to monitor the pressure in pipelines, storage tanks, and various processing units. The unique challenges of this industry, such as high pressures, extreme temperatures, and corrosive environments, require pressure gauges that are not only accurate but also robust and durable.

One of the key applications of pressure gauges in the oil and gas industry is in drilling operations. During drilling, maintaining the correct pressure is crucial to prevent blowouts, which can lead to catastrophic accidents. Pressure gauges help operators monitor the pressure in the drilling mud, ensuring that it is within safe limits. Additionally, in refining processes, pressure gauges are used to control the pressure in reactors and distillation columns, optimizing the yield and quality of the final product.

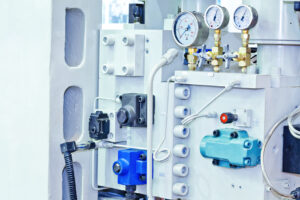

To meet the specific needs of the oil and gas industry, pressure gauges are often made from materials that resist corrosion, such as stainless steel or Monel. They are also designed to withstand harsh conditions, including vibrations, shock, and extreme temperatures. Some gauges are even filled with a liquid, like glycerin, to dampen the effects of vibrations and prevent damage to the gauge mechanism.

In conclusion, pressure gauges in the oil and gas industry are essential tools that help maintain safety and operational efficiency. Their ability to provide accurate and reliable pressure readings in extreme conditions makes them indispensable in this high-stakes industry.