The air pressure correction method is a method of using compressed air or oxygen to correct the pressure of the pressure gauge. It has a simple structure and is easy to use. It is suitable for the calibration of flammable gas pressure gauges with a pressure in the range of 0 to 1.47 MPa.

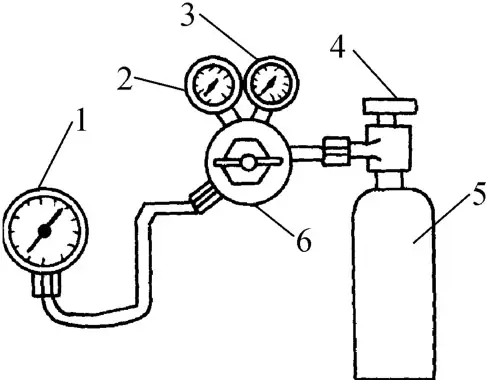

1. Pressure gauge to be calibrated

2. Pressure gauge A

3. Pressure gauge B

4. Air pressure tank valve

5. Air pressure tank

6. Pressure reducing valve

The air pressure calibration device is composed of a gas storage tank, a pressure reducing valve, a gas storage tank valve, and a pressure gauge. The connection method is shown in the figure above, and the operation steps are as follows:

(1) Open the gas storage tank valve to allow the pressure gas in the tank to flow into the inlet end of the pressure-reducing valve. At this time, the reading indicated by the pressure gauge A at the inlet end is the pressure value in the tank.

(2) Open the pressure-reducing valve slightly. At this time, both the outlet pressure gauge B and the gauge being calibrated have a certain reading, which is compared with the pressure reading of the gauge being calibrated to obtain the pressure error of the gauge being calibrated.

(3) Close the pressure reducing valve, then loosen the inlet pipe joint of the meter being calibrated, let off the gas, and then tighten it.

(4) Adjust the pressure gauge to be calibrated. After adjustment, perform the calibration according to the above steps and repeat the calibration many times until the pressure error reaches the standard requirement.

Note: Normally oil filled pressure gauges can only be calibrated with compressed air, not with oxygen, to prevent the explosion.