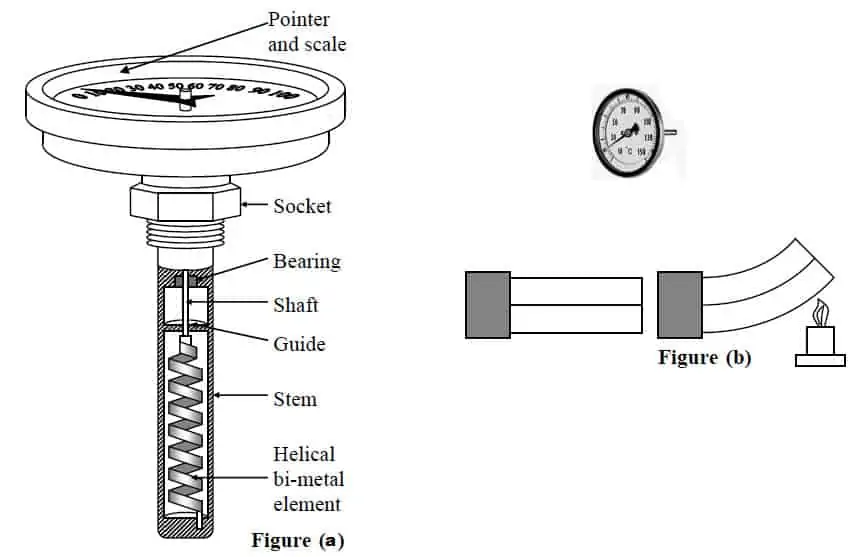

What Is Bimetal Thermometer

The bimetal thermometer combines two metals with different linear expansion coefficients, and one end is fixed. When the temperature changes, the two metals have different thermal expansions and drive the pointer to deflect to indicate the temperature. This is a bimetal thermometer. The temperature measurement range of the bimetallic thermometer is -80~500C. It is suitable for temperature measurement when the precision is not high in the industry. As a kind of temperature sensing element, the bimetal can also be used for automatic temperature control.

The bimetallic thermometer uses a hot bimetallic piece wound into a threaded shape as a temperature sensing device, and it is installed in a protective sleeve. One end is fixed, called the fixed end, and the other end is connected to a thin shaft, called Free end. A pointer is provided on the free end spool. When the temperature changes, the free end of the temperature sensing device rotates accordingly, driving the pointer on the thin shaft to produce an angle change, and the corresponding temperature is indicated on the dial.

Installation of bimetal thermometer

For the installation of bimetal thermometers, attention should be paid to accurate temperature measurement, safety and reliability, and convenient maintenance, and does not affect equipment operation and production operations. These requirements must be met. When choosing the installation position and insertion depth of the thermal resistance, pay attention to the following tips:

1.In order to have sufficient heat exchange between the measuring end of the thermal resistance and the measured medium, the location of the measuring point should be selected reasonably and try to avoid installing thermal resistance near the dead corners of valves, elbows, pipes and equipment.

2.The thermal resistance with protective sleeve has heat transfer and heat dissipation loss. In order to reduce the measurement error, the thermocouple and thermal resistance should have sufficient insertion depth

- For the thermal resistance measuring the temperature of the fluid in the center of the pipeline, the measuring end should generally be inserted into the center of the pipeline (vertical installation or inclined installation). If the pipe diameter of the fluid to be measured is 200 mm, the insertion depth of the thermal resistance should be 100 mm

- For temperature measurement of high-temperature, high-pressure and high-speed fluids (such as main steam temperature), in order to reduce the resistance of the protective sleeve to the fluid and prevent the protective sleeve from breaking under the action of the fluid, a shallow insertion method of the protective tube or a hot-jacket thermal resistance can be adopted . Shallow plug-in type thermal resistance protection sleeve, the depth of its insertion into the main steam pipe should not be less than 75mm; the standard insertion depth of thermal sleeve type thermal resistance is 100mm

- If you need to measure the temperature of the flue gas in the flue, although the flue diameter is 4m, the insertion depth of the thermal resistance is 1 m.

- When the measuring original insertion depth exceeds 1m, it should be installed vertically as much as possible, or a support frame and protective sleeve should be installed